In the Industry 4.0 era, it is necessary to have solutions that make it possible to compensate for peaks in resource capacity utilization.

The accuracy with which the Inspection Bench works is in the order of hundredths of a millimeter because the vision system ensures that the parts are within the allowable tolerance for that product.

As it is a vision system, the parts are photographed and the data are extracted and compared with the customer's database.

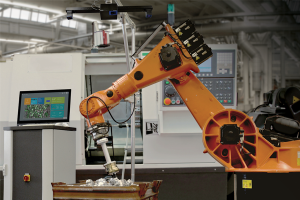

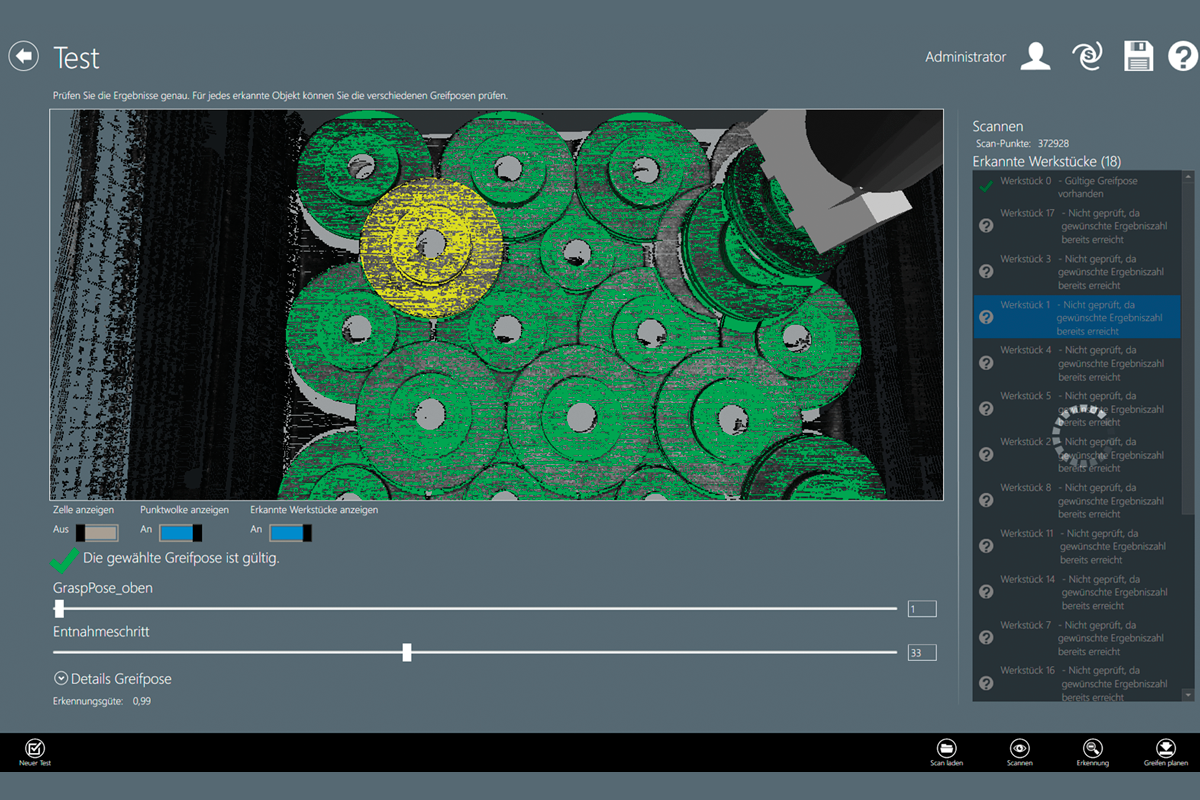

3D Vision System

The 3D vision system (Bin Picking) allows you to determine with extreme precision the position of any object/part, even randomly distributed and without classification.

High-capacity laser sensors can cover great depths.

From the references collected with the reading, the system sends the coordinates for the robot to perform its task starting with the best “handle” position with agility and efficiency to the robotic system.

3D Bin Picking Vision System

- Allows you to determine with extreme precision the position of any object/part, even randomly distributed and without classification.

- High-capacity laser sensors can cover great depths.

- From that on, the system sends the coordinates to the robot to perform its task.